-

Mining Crusher Machine

-

Jaw Stone Crusher Machine

-

Double Roll Crusher Machine

-

Hammer Mill Crusher

-

Gold Washing Plant

-

Gold Wet Pan Mill

-

Ball Mill Crusher

-

Raymond Grinding Mill

-

Impact Stone Crusher Machine

-

Hydraulic Cone Crusher

-

Vertical Compound Crusher

-

High Efficiency Fine Crusher Machine

-

Crusher Spare Parts

-

Ore Dressing Equipment

-

Vibrating Screening Machine

-

Auxiliary Mining Machinery

-

Mark JoePerfect seller, excellent product, superb price, and straightforward shipping. We could not be happier with Henan Ascend Machinery and Equipment Co Ltd - Communication was excellent throughout, so easy to contact and always responded extremely quickly. Definitely looking forward to future orders with this company.

Mark JoePerfect seller, excellent product, superb price, and straightforward shipping. We could not be happier with Henan Ascend Machinery and Equipment Co Ltd - Communication was excellent throughout, so easy to contact and always responded extremely quickly. Definitely looking forward to future orders with this company. -

Remember AkidoI buy two 1600 wet pan mill and 2 jaw crushers from Ascend machinery company, the quality is very good and Wilson is very helpful in assisting me all the techinical support. We have produced more than 300KG gold. Will continue work with them and go together with this company!

Remember AkidoI buy two 1600 wet pan mill and 2 jaw crushers from Ascend machinery company, the quality is very good and Wilson is very helpful in assisting me all the techinical support. We have produced more than 300KG gold. Will continue work with them and go together with this company! -

Jose AnthonyAscend company provided me good after-sale service after buying their gold ore dressing plant, that’s important to me, will consider to buy the second plant

Jose AnthonyAscend company provided me good after-sale service after buying their gold ore dressing plant, that’s important to me, will consider to buy the second plant

Ball Mill Laboratory 1-10 Ton Per Hour Capacity Powder Making For Ceramic industries

| Place of Origin | China |

|---|---|

| Brand Name | ASCEND |

| Certification | CE/ISSO9001 |

| Model Number | different needs |

| Document | Product Brochure PDF |

| Minimum Order Quantity | 1 set |

| Price | USD 3500-30000 Per set |

| Packaging Details | Water and rust proof in wooden box or cotainer |

| Delivery Time | 10 days |

| Payment Terms | Western Union, T/T, L/C, MoneyGram |

| Supply Ability | 10 set per month |

| Material | SteelIron,High Manganese Steel | Dimensions | Customer Needs |

|---|---|---|---|

| Application | Mining,Industry,cement,mine | Process | Raw Material Quenching |

| Usage | For Ball Mill And Rod Mill | Type | Chrome Forged Steel Ball For Ball Mill |

| Quality Control | Professional Inspection | ||

| Highlight | Ceramic Industries Ball Mill,Laboratory Ball Mill,Powder Making Ball Mill |

||

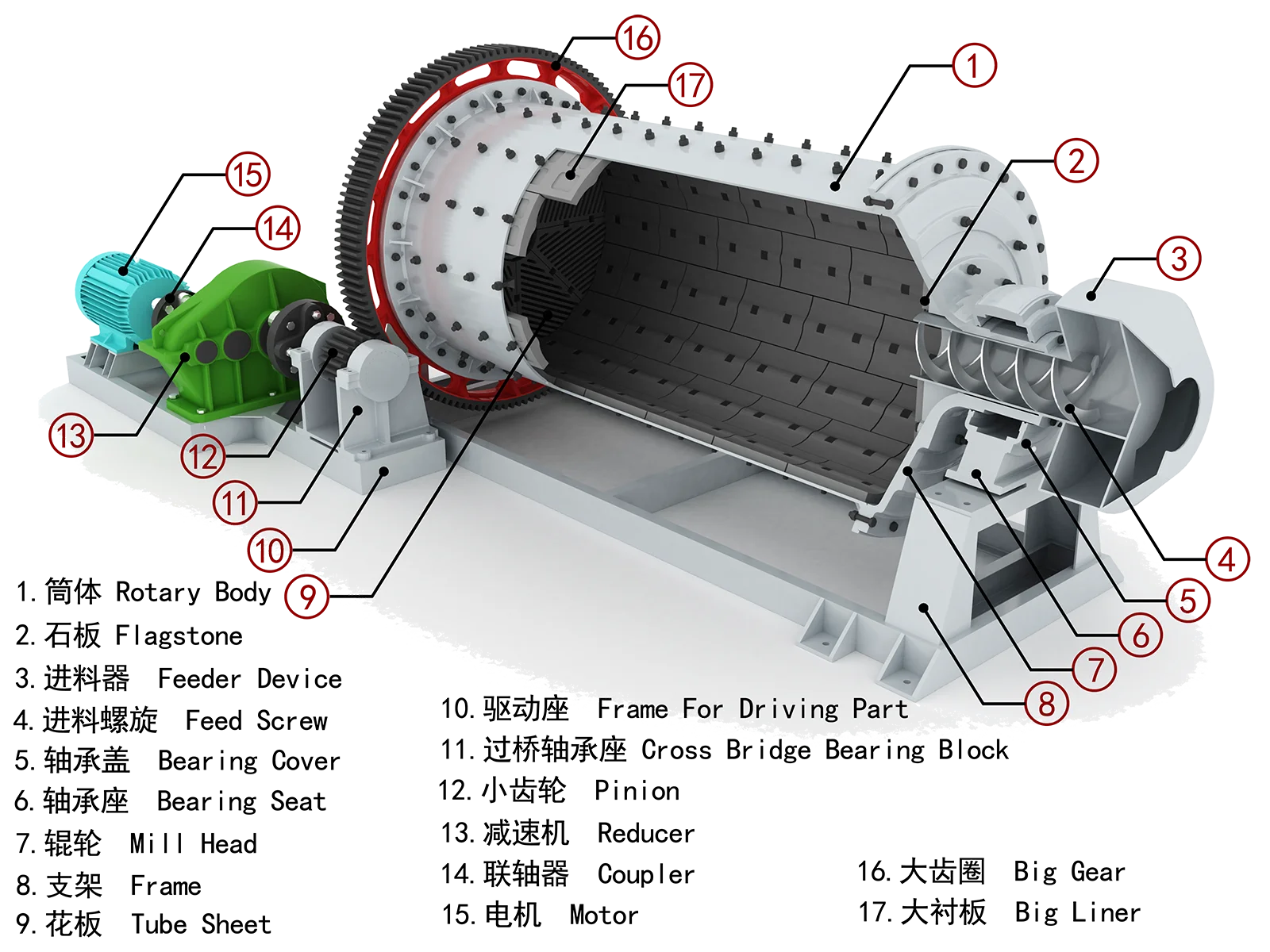

Stone Rotary Ball Mill Basalt Granite Clay Grinding Machine For Gold Concentrate Machinery

Product Descriptio

Applications of GMF Superfine Ball Mill Grinding Production Line:

- (1) Soft materials: calcite, marble, limestone, kaoline, gesso, barite, coal ash and slag, etc.

- (2) Hard materials: carborundum, brown corundum, superfine cement, zirconium sand, and fire-proof materials, etc.

- (3) High purity materials: quartz, feldspar, α-alumina, glass fine bead, etc.

- (4) Metal powders: zinc powder, aluminum powder, iron powder, and molybdenum powder, etc.

Advantages of Ball Mill

2. Several times of classification could be obtained:

Finished product fineness after classification: 120-200mesh,or 200-325mesh,or 325-2500mesh,or 2500- 6,250mesh (d97≤2um).According to customer requirements.

3. Adopted highly advanced self-diffluent classification system:

4. Scientific grinding medium enable us to produce large quantity superfine particles.

5. Different lining boards and grinding mediums are available for milling different materials, so as to guarantee the purity and whiteness of finished products.

6. Scientific machine structure enables a lower investment cost;

7. Low failure rate and stale operation: because our ball mills and classifiers in the production lines are PLC controlled and have high automation;

8. Negative pressure production condition gives a good production environment;

9. High annual production capacity: 5-500 thousand tons.

Detailed Images

Spare Parts

Working Principle

The wet ball mill needs to add an appropriate amount of water or absolute ethanol during the grinding process, which means that there are certain requirements for the concentration of grinding. The amount of water is determined by the nature of the material. Qualified materials are discharged out of the cylinder through the discharge part, and unqualified materials are returned to the wet ball mill again for re-grinding.

Main Technical Parameters

| Model |

Shell rotation speed (r/min) |

Ball load (t) |

Feeding size (mm) |

Discharging size (mm) |

Capacity (t/h) |

Motor power (kw) |

Total weight (t) |

| 900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| 900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| 1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| 1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| 1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| 1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| 1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| 1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| 1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| 1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| 1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| 1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| 2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| 2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| 2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| 2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| 2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| 2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| 2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| 2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| 2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

Packing&Shipping

Working Sites

Company Profile

- Henan Ascend Machinery & Equipment Co., Ltd. was established in 2005 and it is located in the high-tech zone of Zhengzhou City, Henan Province. As a technology driven mining equipment company, it is committed to the R&D, production, sales and after-sales service of mining machinery and equipment.

- The company's main products are crushers, grinding mill equipment, mineral beneficiation equipment, rotary dryer and crusher & grinding mill spare parts. In addition to the Chinese domestic market, Ascend machinery expands its business in more than 160 countries and regions.

Our Workshop

FAQ

Q1. Are you factory or trading company?

We are factory specialized in manufacturing stone crushers, grinding mills, beneficiation equipments and other mining equipments. Our office and factories are based in Zhengzhou, China. Because we are factory, so we can guarantee the machine quality and we can give you very competitive factory price without extra agent cost.

Q2. To which country your products have been exported before?

In Africa, We have exported to Sudan, Kenya, Zambia, Ethiopia, Zimbabwe, Guinea, Nigeria and so on. We also exported South Africa, Chile, Peru, Ecuador, New Zealand, America, Austrilia more than 160 countries. Our equipment and service have won very high reputation in these countries.

Q3. How will you help the customer install the equipment?

We will send our senior engineer to your place to guide the installation and commissioning.

Q4. How about the wear parts supply?

We offer wear parts to our customer with our most favorable price. If there are problems you could not handle, we will send our technicians to your place.

Q5.What about the payment method?

T/T, Paypal, Western Union, L/C is available.

Q6.What about after-sale service?

12 months warranty for all kinds of products; and you will get our 7*24h online service.

Related Products

Ball Mill Jaw Crusher Hammer Crusher

2-Roller Crusher Cone Crusher Impact CrusherContact Us

For more information, pls