high manganese sandvik stone crusher

,metso sandivik cone crusher parts

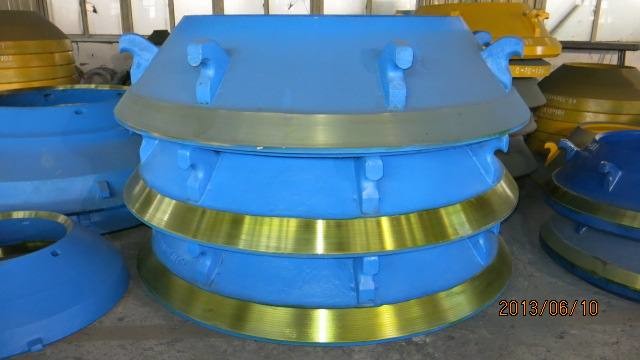

High Quality Mn18Cr2 Sandivik Cone Crusher Bowl Liner Mantle And Concave Spare Parts

Cone crusher, divided into spring cone crusher and hydraulic cone crusher, is the secondary crusher in mining and quarry industry. It is used to crush medium hard and extremely hard stone, like basalt and granite. The main wear spare parts of cone crusher is mantle and concave, also called bowl liner.

Cone crusher mantle and concave spare parts is usually made of high manganese 13 or high manganese 18, depending on the stone feature. Manganese alloy features " work harden", means the harder the stone, it will hit the mantle and concave surface harder, then the surface of the spare parts will last longer. Manganese content range usually between 13% and 22%, and is usually reference as follows:

- 14% = 13-14% MN

- 18% = 17% - 19% MN

- 21% = 21% - 24% Mn

- Casting with any above percentage depends on the customer working situation. Usually the high percentage manganese will last longer, but it is much subject to the material to be crushed. So before casting, the customer should communicate more technical details with our sales engineer. And usually we can cast according to the drawing or spare parts dimensions offered by the customer.

Production process

Package and delivery